Production Rate: Up to 40 bundles per minute

Track Size:

- 600mm x 600mm (23.5″ x 23.5″)

- 800mm x 600mm (31.5″ x 23.5″)

- 1000mm x 800mm (39.4″ x 31.5″)

Electrical: 100V – 600V, 50/60 Hz, 0.2 – 0.24 kVA

Conveyor: Powered belt Conveyor (Max table weight 110Lbs)

Table Height: Standard: 32.25”-36.5” (820mm-925mm), Low: 28.75”-32.85” (730-835mm)

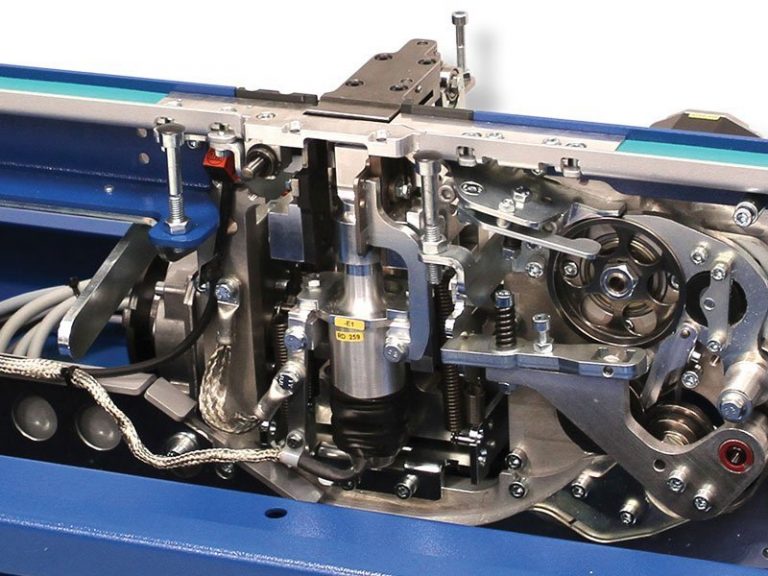

Strapping: SoniXs® sealer runs PP strap from 5-12mm and select PET straps. Optional heat sealer runs PP strap from 5-12mm.

Strap Tension: Infinitely adjustable up to 60 lbs.

Strap Seal: SoniXs® Ultrasonic seal with DC brushless direct-drive motor

Seal Location: 600mm x 600mm center seal. Other sizes offset 12” from arch corner, control panel side

Machine Shipping Weight: Approx. 675 Lbs.

Casters: Two swivel-lock casters Two fixed casters