Specialty Solutions for Complex Box Bundling

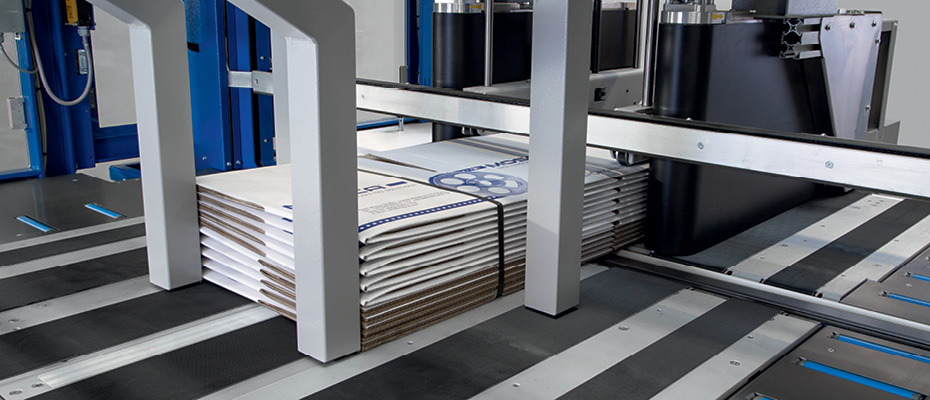

As packaging plays an increased role in product marketing and serves to improve brand awareness, Mosca GmbH of Waldbrunn, Germany -the world technology leader in strapping system design and manufacture, has introduced the UCB bundle strapping system to assist those efforts. The UCB was developed to secure bundles of specialty boxes with unprecedented productivity, gentle handling and operator safety.

UCB Integration Capability

The UCB is capable of being integrated into a fully automatic Flexo-Folder-Gluer (FFG) line. However, the system’s ‘specialty’ focus is on specialty folder production and the related bundling of shingled streams of decorative four and six-sided boxes that require a close operator-machine interface and precise control of the squaring and strapping functions to protect the visual esthetics of the product.

In the typical Specialty Folder arrangement, a shingled bundle stream will be conveyed to an in-line air table that assists an operator in creating bundles to be fed into the strapping machine. UCB can be set up for either left or right-hand operation. The operator builds a bundle and slides it onto the UCB’s entry belts where the machine takes over with squaring and strapping. The standard model includes five-sided squaring with single or double backstop (for two straps per bundle); powered side belts for precise lateral guidance; powered top belts for smooth transport, and electrically driven press for load stability during strapping operation. A rear bundle pusher is optionally available for full six-sided squaring.

Setup changes are made by operator input of bundle dimensions and strap locations at the touch screen HMI, preset stored recipes, or via network data communication.

The strapping function is performed by a Mosca ROMC-6 bottom seal strapping machine that conveniently slides into position in the conveying/squaring section of the system. The strapper features Mosca’s proprietary SoniXs® ultra-sonic sealing technology and Mosca’s efficient closed track system for extremely high cycle reliability. The ROMC-6 can be outfitted with an optional dual-dispenser system and automatic coil change to minimize the impact of coil changes on uptime and throughput. A manual coil change takes a minute or more, after the operator arrives at the dispenser. The auto coil change option reduces this to 12 seconds without requiring on-demand operator participation.

Safety First

The UCB meets demanding CE operator safety requirements, without compromising productivity. Throughput speed for automatic operation is up to 32 bundles per minute. In specialty folder operations, processing speed is typically controlled by the operator and is considerably lower. However, by removing safety risks, offering either left or right-hand operator station configuration and by taking full control of bundles immediately following operator release, UCB offers productivity advantages over competitive products.

A Solutions Team: UCB and S-ATRS-6

UCB comes in widths of 1250mm (49″) or 1650mm (65″). It can handle bundles as small as 150mm (6″) long x 120mm (5″) wide and 20mm (1″) high. Maximum bundle length is 1200mm (47″). When paired with the Mosca S-ATRS-6 strapping system, also focused on shingled stream box production from specialty folder-gluers, the two products provide an appealing solution portfolio for this application. S-ATRS, which is also equipped with proprietary SoniXs® sealing technology has been the industry standard for years, and remains a great solution for most shingled stream strapping requirement. The UCB offers an answer for situations that require CE safety compliance, more sophisticated bundle handling for difficult shapes or esthetically sensitive products, and as noted, can be integrated into a fully automated line where bundles are built automatically by the conversion equipment, rather than by an operator.

EAM-Mosca Corporation provides high-performance strapping system solutions to a variety of industries, including food, graphic arts, mailing, fulfillment, logistics, corrugated, wood, and other industrial or consumer goods. We combine innovative equipment with strapping materials manufactured to maximize machine performance and customer support programs that help our customers meet their performance and productivity goals.

To learn more about any of EAM -Mosca’s other productivity enhancing strapping systems, please call us at 800-456-3420, or email us at info @eammosca .com. You can also connect with EAM-Mosca on YouTube, Twitter, Linkedln and FaceBook via the links above.