Productive End-of-Line Packaging Solutions: Cobots & Strapping Machines Are Your Powerful Duo

In today’s world, human line operators may be difficult to find or retain. A 2023 study by the National Association of Manufacturers (NAM) found that 77% of manufacturers expect ongoing difficulties in attracting and retaining workers. Thankfully, technology is making robotic solutions in the manufacturing space more adaptable and affordable; as a result, robots and cobots are gaining popularity as an indispensable component of end-of-line packaging operations, transforming the manufacturing industry.

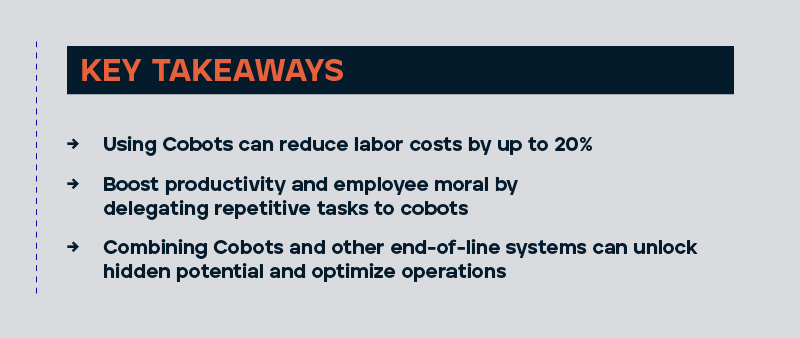

Businesses that want to streamline their productions and increase operational reliability should consider how they can integrate robots into their production lines. Studies suggest that cobots can boost productivity by up to 40% and reduce labor costs by 20%. (Source: McKinsey & Company). But how exactly do robots and cobots help? Let’s dive into the benefits and advantages of integrating robots into end-of-line strapping systems.

The Cobot Revolution in Packaging

Collaborative robots, or cobots, offer unique advantages and can supercharge productivity. Unlike traditional industrial robots, cobots are designed to work safely alongside humans, offering flexibility, ease of programming, and a smaller footprint. Cobots are:

- Lightweight and compact: Cobots can easily fit into existing workspaces without significant layout changes, reducing the cost and time constraints of adapting new machinery into existing lines.

- Easy to program: Extensive coding knowledge is not required for operating Cobots. Many of these systems utilize an intuitive drag-and-drop interface, allowing the operator to program and make adjustments with ease.

- Safe and collaborative: Built-in sensors and a limited range of motion prevent harm to human workers.

- Versatile: Capable of handling diverse tasks, these devices can succeed in performing simple tasks, such as picking and placing, to more complex operations such as assembly and inspection

Benefits and Unique Advantages of Robots in End-of-Line Packaging Systems

Robots in an end-of-line packaging system bring independent, programmable capabilities to repetitive operations. Cobot programming is more straightforward and easily adapted, often supporting operators working to meet variable, shorter-run requirements. Advantages and benefits include:

- Boost Efficiency: Cobots tirelessly perform repetitive tasks, freeing up human workers for higher-level activities.

- Improve Accuracy: Precise movements and sensors minimize errors, reducing defective products and rework.

- Enhance Safety: No more manual lifting or exposure to hazardous tasks. Cobots can handle the heavy, more strenuous work, protecting your team. A 2021 study by the University of Pittsburgh found that manufacturing facilities with cobots had 11% fewer injuries per 100 employees than those without. (Source: University of Pittsburgh)

- Increase Scalability: Easily add or remove cobots as production needs fluctuate, adapting to dynamic workflows.

- Reduce Costs and Increase ROI: Automation reduces labor costs, improves product quality, and minimizes downtime, leading to significant savings. Studies estimate up to 20% savings on labor costs through automation and optimized workflows. (Source: McKinsey & Company)

- Improve Employee Morale: Repetitive tasks are delegated to cobots, allowing human workers to focus on more rewarding and engaging activities

Cobots and Strapping Systems: A Powerful Duo

Cobots and Strapping Systems: A Powerful Duo

Combining strapping systems with cobots, the strengths of each system to your advantage for a dynamic, efficient, reliable, and seamless packaging solution.

Mosca has long focused on delivering superior, operator-friendly end-of-line packaging systems for various products and processes.

Always on the forefront of innovation, Mosca has adapted its products to smoothly into automated partnerships with independent industrial robots and cobots that work alongside human operators in applications ranging from case filling to box closing to palletization.

In simple, repetitive applications, strapping systems can operate relatively independently from the cobots, accepting packages to be strapped or handing strapped products off to a robot for the next processing step.

In systems with changing requirements, the strapping system can be integrated into a broader control system that chooses strap quantities and positions to fit specific pre-programmed product needs. Similarly, the robot can be programmed to perform more than one function.

Popular Applications:

Palletization

Need to palletize? A cobot palletizer might be the way to go. Thanks to their robust design and precise controls, cobot palletizers can quickly and accurately lift heavy boxes and bags to be palletized. In addition, a cobot’s adaptability to different box sizes and weights makes it incredibly versatile. Follow with a strapping system or wrapping machine for product securement for transport.

Case Erector and Packing

Make light work of case erection and packing. With minimal footprints, cobots can help you work alongside your workers to unfold and shape corrugated boxes for easy, smooth, and quick case erection and packing. Combine with a palletizer and strapper for the ultimate automated end-of-line solution.

Product Manipulation

A Cobot’s sweet spot is repetitive action. Take advantage by using them for mundane, repetitive tasks like product manipulation. Do you need to move product from one conveyor to another, or align the product for inspection and labeling? You may benefit from using a cobot than human operators, who could be used for more complex tasks elsewhere, increasing job satisfaction and accuracy.

See Case Packing and Pallet Strapping In Action!

The example in the video below includes both case packing and pallet strapping. An automatic strapper straps individual boxes closed. The boxes are then conveyed to a downstream pick-up point, where a robot picks and places them into a second strapper that secures three-box bundles palletized by the robot. The pallets can then be secured for storage or shipment by a strapper or stretch wrapper. The example illustrates how controls can be integrated between the strapper and robot to provide the required product configuration and security.

This example demonstrates how the one-time programming for the strapper and robot and the 24 hours a day, seven days-a-week capability of the equipment can simplify and increase production of the affected processes versus trying to train and manage a multi-shift human labor force.

Case Study: Cobot & Strapper Combo Reduces Labor Costs By Over 33%

A simple example of a relatively independent integration of strapping and robotic material handling comes from an EAM-Mosca customer. The customer reduced floor space, and labor costs by more than 33%!

Initially using manual strappers, they upgraded to an automated strapping and robotic palletizing system for packaging plastic shelves sold to big box home improvement stores. The strappers use internal sensing systems in a coordinated but independent way to detect package movement and execute pre-programmed operating sequences. While this is a straightforward system, savings

EAM-Mosca has been part of similar strapper-robot automation solutions for products ranging from roof tiles to basketball backboards. The concept has been functionally and economically proven many times over.

Unlock Your Full Potential with EAM-Mosca’s Packaging Solutions

The benefits of integrating your operations with robots and cobots are numerous and varied. You should, however, consider your specific needs and explore how they can best integrate with your existing workflows to unlock their full potential and transform your packaging process.

From a safer work environment to increased productivity, there is no doubt that cobots are the future of manufacturing.

Partner with an innovative end-of-line strapping system supplier

EAM-Mosca supports applications that range from operator-initiated machine cycling to fully automated package transport, positioning, and strapping. We can integrate our products into most situations with equipment ranging from the simplest bundlers to fully automated bundling, pallet strapping, unitizing, and stretch wrapping systems. We can design integrated controls when appropriate and can support broader-based system integrators as needed to provide customers with productive and economically justifiable solutions to their end-of-line packaging needs.

Editor’s Note: Original article posted October 2022