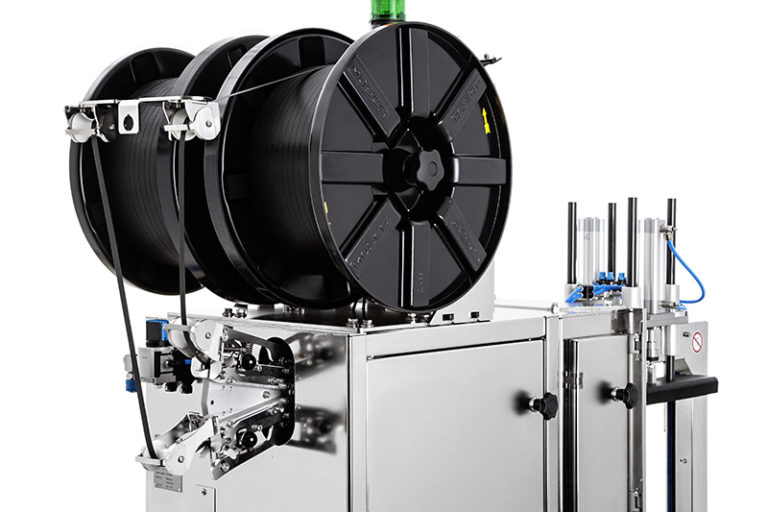

ROMS6-VA SoniXs®

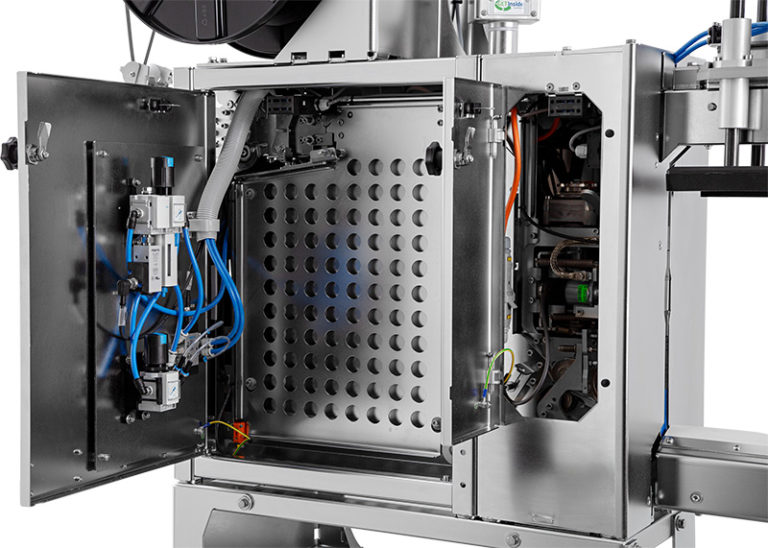

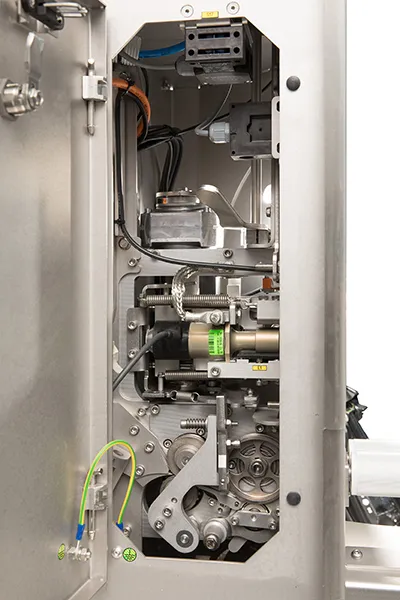

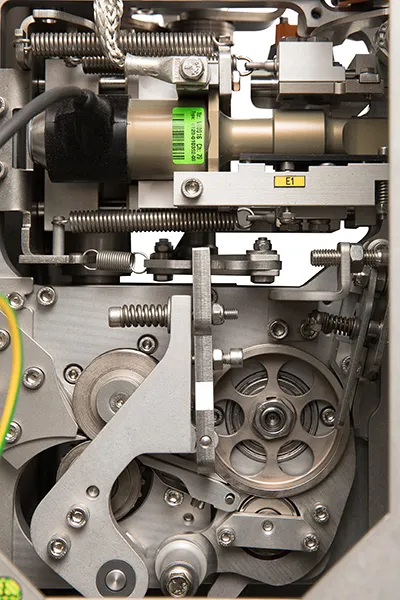

The ROMS6-VA SoniXs is an automatic strapping machine engineered for harsh food processing environments. Built to IP56 protection standards, the robust stainless-steel enclosure provides the best protection available in the market today. An IP (ingress protection) rating classifies the degree of protection against the intrusion of solid objects, dust, accidental contact, and water in electrical enclosures.

System Includes:

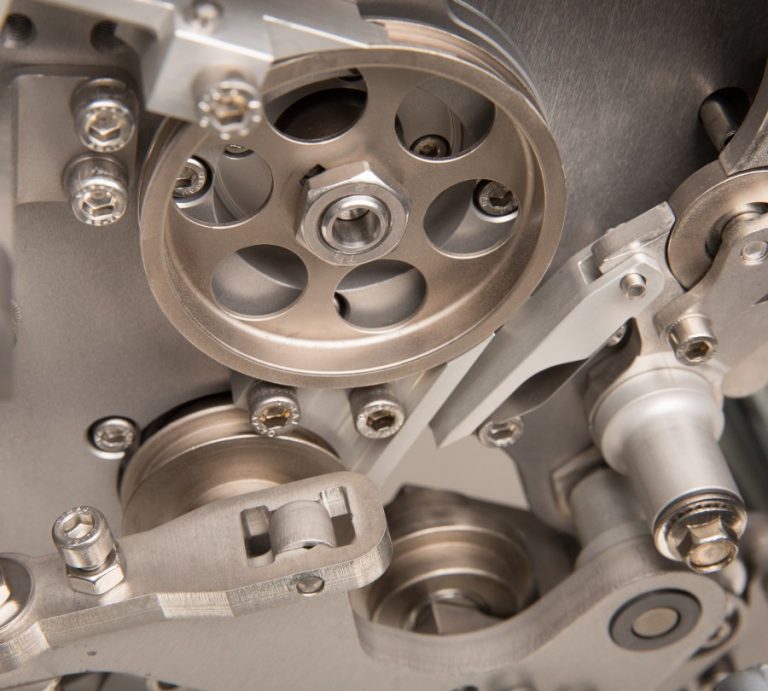

- Mosca’s SoniXs ultrasonic sealing head for superior seal performance in cold, wet environments.

- Corrosion-resistant components and stainless steel enclosure for increased durability and system life.

- Easy safe Cleaning – IP56 protection ensures the system can be hosed down for cleaning and is protected against high-pressure water jets from any direction.