ROM-Fusion

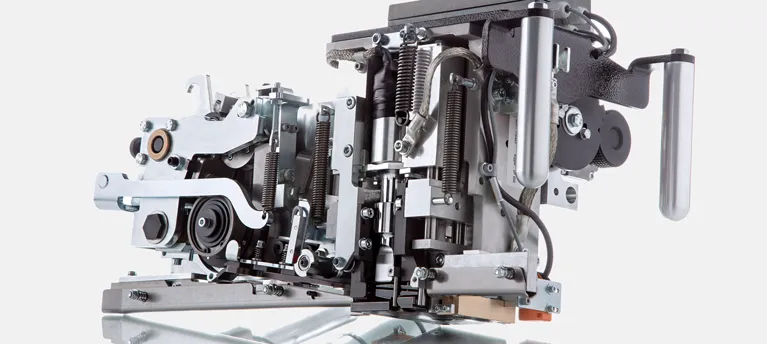

ROM-Fusion

EAM-Mosca develops strapping equipment geared to meet specific needs within vertical industries. We are often able to broaden our successes across industry lines to provide an outstanding array of innovative solutions.

16 Inch PET

16 Inch PET

We offer a variety of sizes, colors, break strengths, and either bulk pallet loads or cartoned product. Most strapping products are sold from stock.

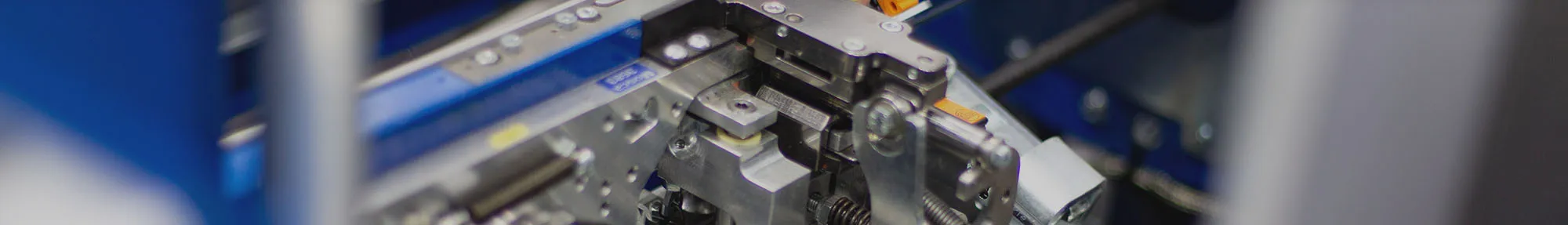

Mosca’s proprietary Sonixs ultrasonic sealing heads have revolutionized strapping systems offering significant and proven advantages over traditional heat-seal technologies, including cost, maintenance, and longevity across all industries and applications.

Learn More

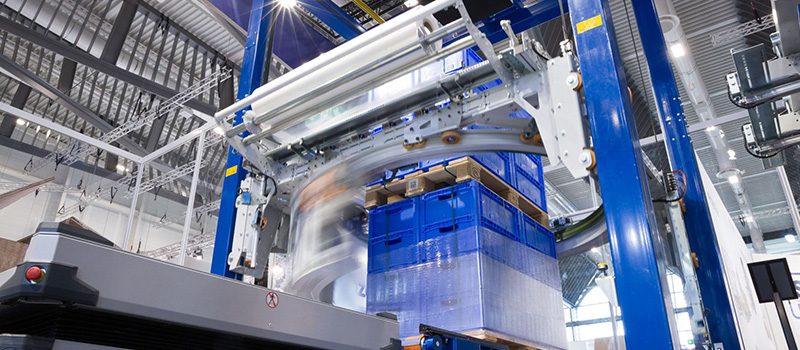

Powered Roller Conveyor

Powered Roller Conveyor

Variety of conveyors are available as part of our complete system offering. Flexible designs to match requirements. Commercially available components make ongoing maintenance convenient.

UBS-Sonixs

UBS-Sonixs

Our engineers provide in-depth consultancy with technical expertise to tailor the best solution for unique requirements.

Movitec rotary ring stretch wrappers provide unparalleled protection, stability, and high performance for palletized and unpalletized loads. Multiple models are available with a variety of features, capacities, and options to suit your application needs.

View Machines

Contact us by phone at (800) 456-3420 by email at info@eammosca.com or via the contact form, on our website.

Yes, we work closely with our customers to provide a solution that will best meet the needs of the application. For more information, visit our custom solutions page. Get in contact by filling out a contact form online, calling us at (800) 456-3420, or emailing us at info@eammosca.com.

We offer a one year warranty on all of our machines and a two-year warranty on all Sonixs sonotrodes and generators.

Yes, we offer 24/7 support for specific high production models through the EAM-Mosca Service department. For more information, please visit our Service and Support page.

Yes, EAM-Mosca offers and encourages customers to participate in the predictive maintenance program, which is performed by our factory-trained technicians. For more information, please visit our Service and Support page.

Ask us for assistance in choosing the right system to meet your requirements, or to suggest new ways our system components can work for you.

EAM-Mosca Corporation, the North American Affiliate of Mosca GmbH, offers a large portfolio of strapping systems to meet a variety of industrial packaging needs.

We strive to be a value-driven leader through responsive field support, application engineering and technological innovations. Our goal is to continuously improve our systems to meet your speed and efficiency requirements, while simultaneously reducing your overall costs.

EAM-Mosca develops equipment geared to meet specific needs within vertical industries. We are often able to broaden our successes across industry lines to provide an outstanding array of innovative solutions. Ask for assistance in choosing the right system to meet your requirements, or to suggest new ways our system components can work for you.