TRC-6 SoniXs®

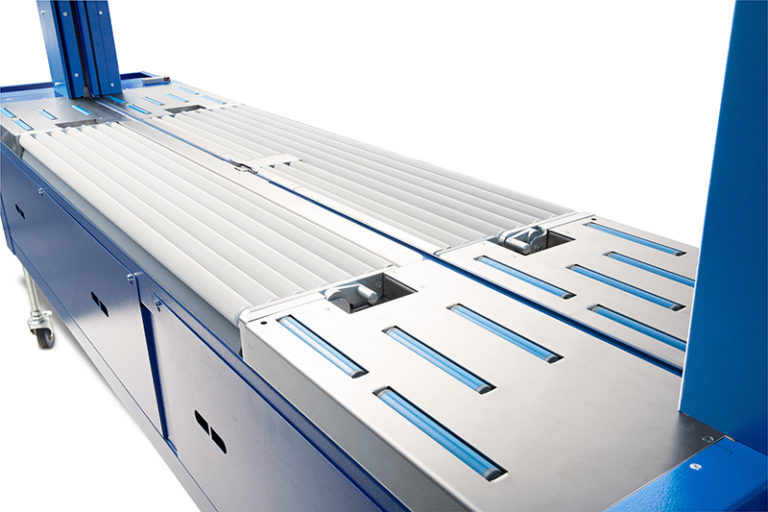

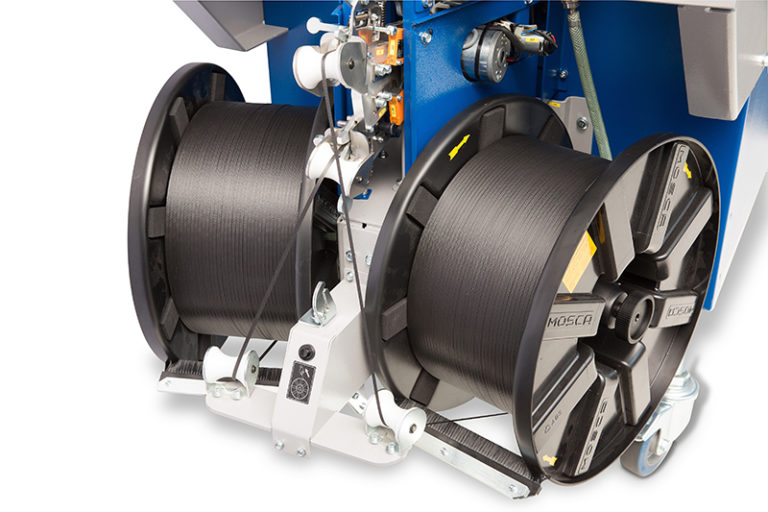

Mosca’s TRC-6 automatic strapping system for corrugated bundles offers advances in mechanical and control technology, a robust new cabinet, new conveyor design, a choice of sealers and a streamlined press mechanism all of which contribute to an exceptionally reliable, high-performance bundler.

The TRC-6 features the innovative Standard-6 precision strap path, a direct-drive sealer with sealed bearing construction, a pivoting control panel for intuitive operator guidance including performance diagnostics.