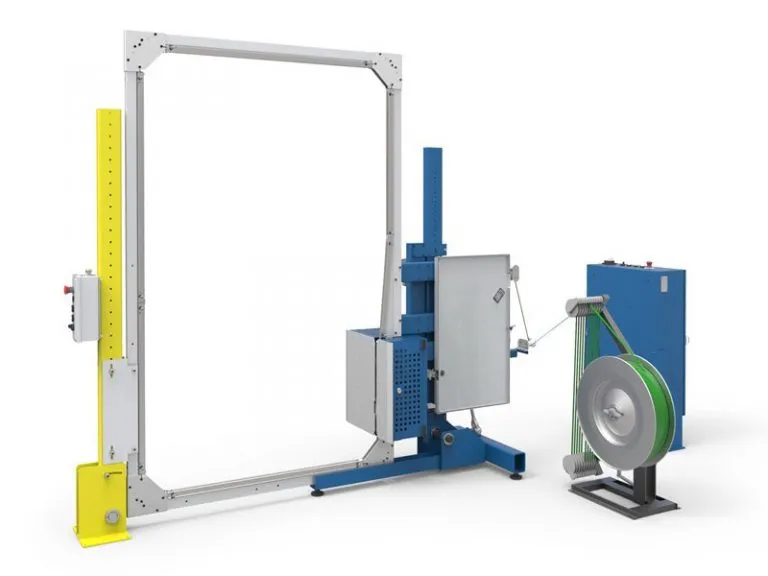

Production Rate: Up to 15 bundles per minute

Track Size: Spring gate tracks: 900mm (35.4″) – 3150mm (124″) W x 1000mm (39.4″) – 3000mm (118″) H in 250mm (9.8″) increments. Other sizes on request

Electrical: 200-575V, 50/60 hz, 3 ph

Conveyor Height: Standard: 8.75” – 24” (Via adjustment screw. No special parts or tools required)

Strapping: SoniXs® sealer runs PP or PET strap 9mm-12mm 750 Lb strength

Strap Tension: Infinitely adjustable up to 450 Lbs.

Strap Seal: SoniXs® ultrasonic seal, with DC brushless direct drive motor

Seal Location: Side Seal

Machine Shipping Weight: Approx. 1200 Lbs.

Casters: Fixed Feet

Additional Features

- Cantilevered head may be positioned up to 14” inside conveyor rails to accommodate package positioning.

- Tracks can be tilted up to 20° to combine with easel style assembly/packing processes.

- Free standing strap dispenser can be in-line with the strapper or oriented at right angles to reduce machine footprint.

- Operated with footswitch, pushbutton, or automatically via signal exchange with an external system controller.

Brush Guides (to keep strap centered and twist free when small packages are used)