Case Study: Pharmaceutical Distributor

Pharmaceutical Distributor Saves Over $18,000 In Labor Costs Per Year By Switching To Mosca

Background

A legacy of more than 100 years has given one of the worlds leading pharmaceutical distributors the success it has today. With a pharmaceutical-centered focus, they maintain their key link in the pharmaceutical supply chain to ensure over 4MM products are shipped each day throughout their network.

As such an essential link in the healthcare system, reliability and efficiency are crucial to distribute life-saving medications to their customers on time.

Challenge

In 2014 the pharmaceutical distributor was struggling to secure plastic totes with the current strapping machines in place.

The strapping machines proved to be so unreliable that shift supervisors were required to “camp out” at the strapping station during their shift. Staff had to constantly troubleshoot issues to keep the strappers running – a highly inefficient, costly, and unnecessary solution that significantly increased downtime. In addition, the pharmaceutical distributor was frustrated with slow service responses and long parts wait times.

With a new expansion planned, they knew their current unreliable strapping machines would not be able to cope with the increased demand. A standardized system across all their locations was also desired and unachievable with their current strapping system supplier.

Solution

Having had many issues in the past with troubleshooting and service, a key feature for the pharmaceutical distributor was our extensive in house training. This training allows our customers to troubleshoot and service parts themselves – saving time, money, and downtime.

As with all our customers, after-sale parts, service support, and training programs are considered a critical element of the EAM-Mosca system. Our responsive field service network is devoted to maintaining peak system operation. When needed, parts can be shipped overnight for ultimate peace of mind.

During the trial, superior feed reliability was immediately evident. Up to 35 packages were now able to be strapped per minute to keep up with the high-speed and high production-driven environment.

The location purchased several more machines during 2015. By the end of the year, six additional company distribution centers ordered Mosca equipment. Included were fully automatic machines on the packing lines, as well as operator cycled machines for the high-security storage areas where securely tying totes and lids in place was the primary focus.

Sometime after the trial began, increased security requirements required the totes to be double strapped for greater tamper resistance. A ROMP-6R SoniXs® tandem system was proposed with integrated controls. By installing a tandem system, line speed could be maintained (even with increased tote straps) while providing a backup capability in the event of a problem with one of the machines.

Results

The high quality of the Mosca strapping equipment with SoniXs sealing technology combined with the EAM-Mosca training programs has enabled many facilities to never need EAM-Mosca field services. Any issues were able to be quickly and efficiently resolved in-house, dramatically reducing the total cost of ownership per machine.

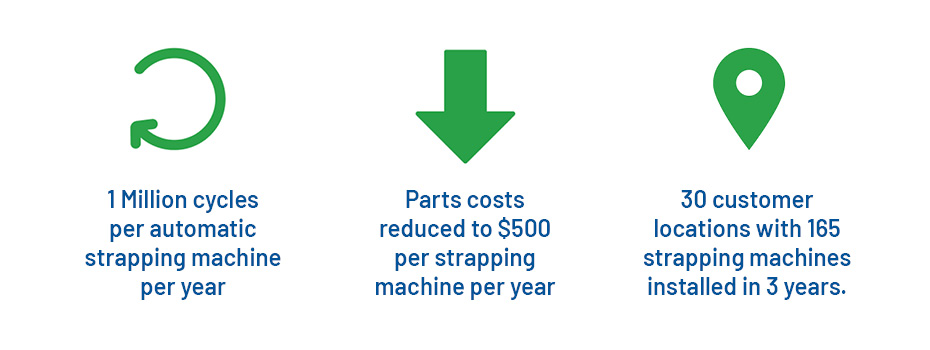

Other results include:

- Increased feed reliability saved $18,000 in labor costs per year

- 1 Million cycles per automatic strapping machine per year

- Parts costs reduced to $500 per strapping machine per year

- Thirty customer locations with 165 strapping machines installed in 3 years.