Benefits of Sonixs® Sealing Technology:

ECONOMICAL

- Proven to provide a reliably stronger seal, reducing cost and amount of strap needed per package with no negative impact on package quality or security.

- Increased seal strength allows strapped products to withstand significant stress, enabling the use of thinner, narrower, less expensive strapping materials without loss of performance.

- Conserves electricity by only using power during the strapping cycle compared to a heat-sealing system that uses constant resources.

- Sonixs® sonotrode and generator include a 2-year warranty.

SUSTAINABLE

- No smoke, fumes or smells.

- Low noise levels.

- Seals PET strap (made from recycled material, and 100% recyclable) providing customers an economical and more environmentally friendly choice for strapping.

- Uses energy only during the sealing process. No warm-up required.

EFFICIENT

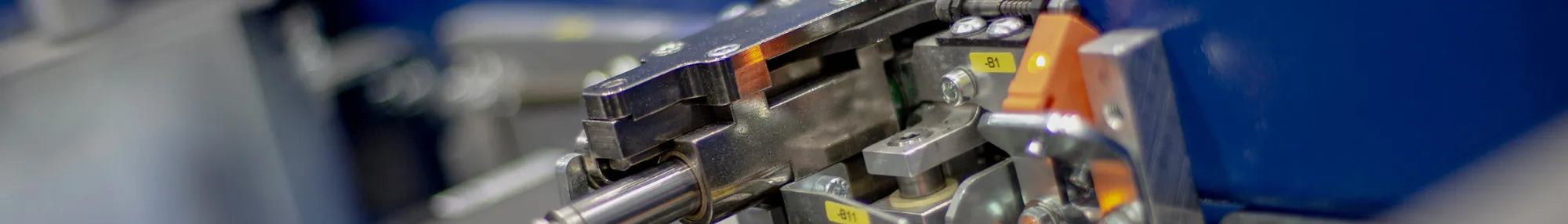

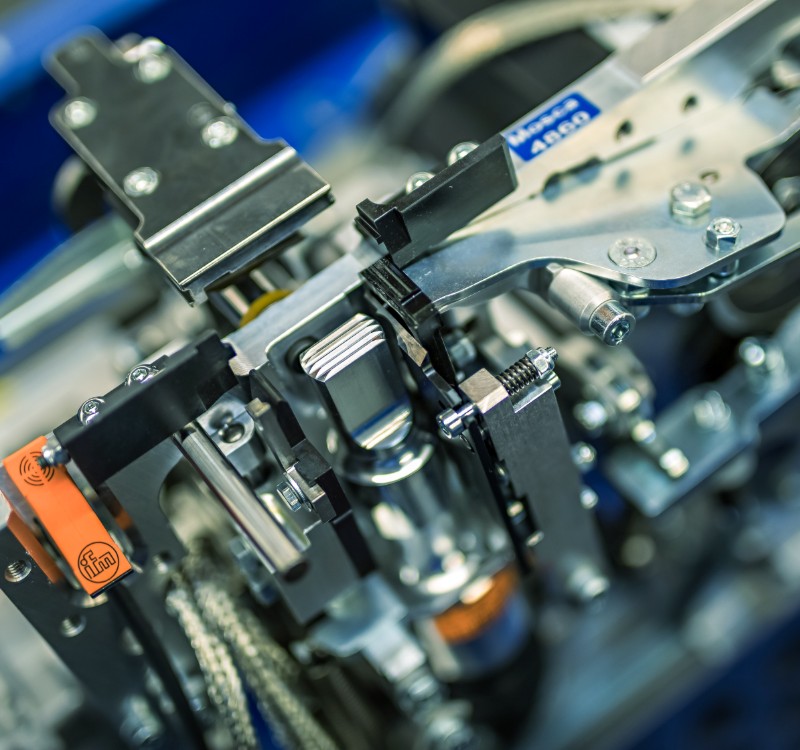

- Innovative lever-style gripper, knife, and sonotrode drive with sealed bearing construction provide maximum durability with less wear and tear.

- Minimal maintenance is required as no residues are created during the sealing process.

- Seals both PP and PET strapping with broad tension ranges, ensuring tight straps and secure bundles under all conditions.

- Easily switch between PP and PET strap when needed. (Minor adjustments and part change may be required.)

- The self-calibrating system monitors major parameters before every seal for consistent sealing in any environment.

- Our tool-less sealing head maintenance for easy and fast maintenance within 30 seconds.