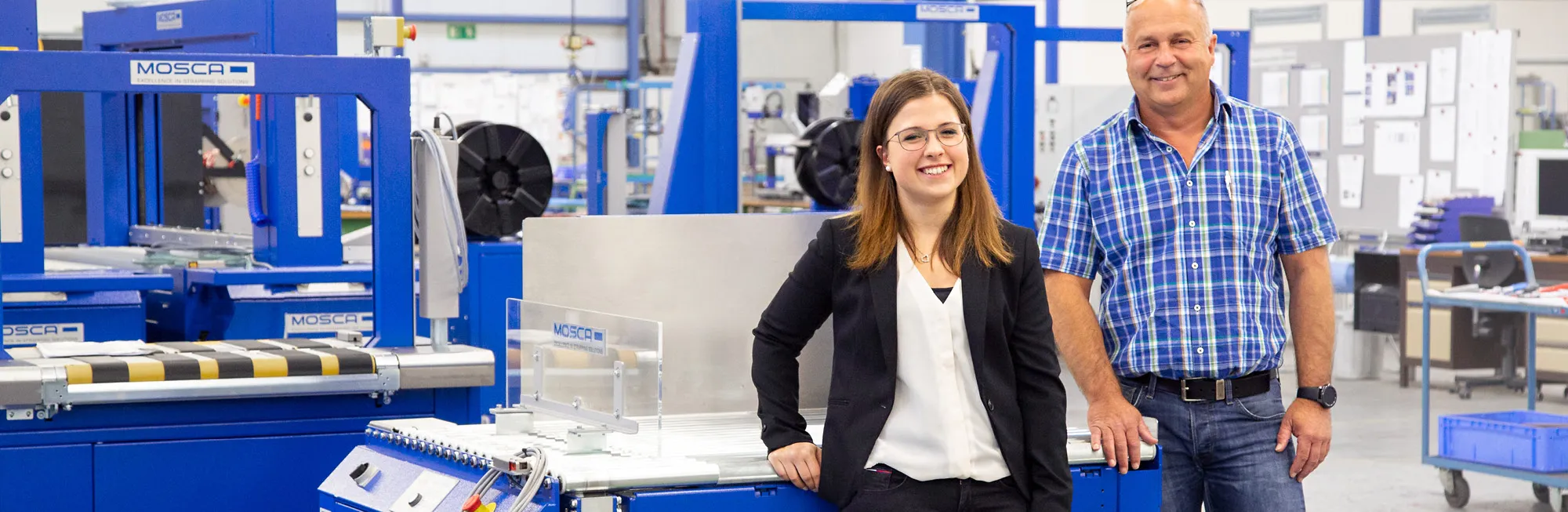

WORKING TOGETHER FOR THE BEST SOLUTION

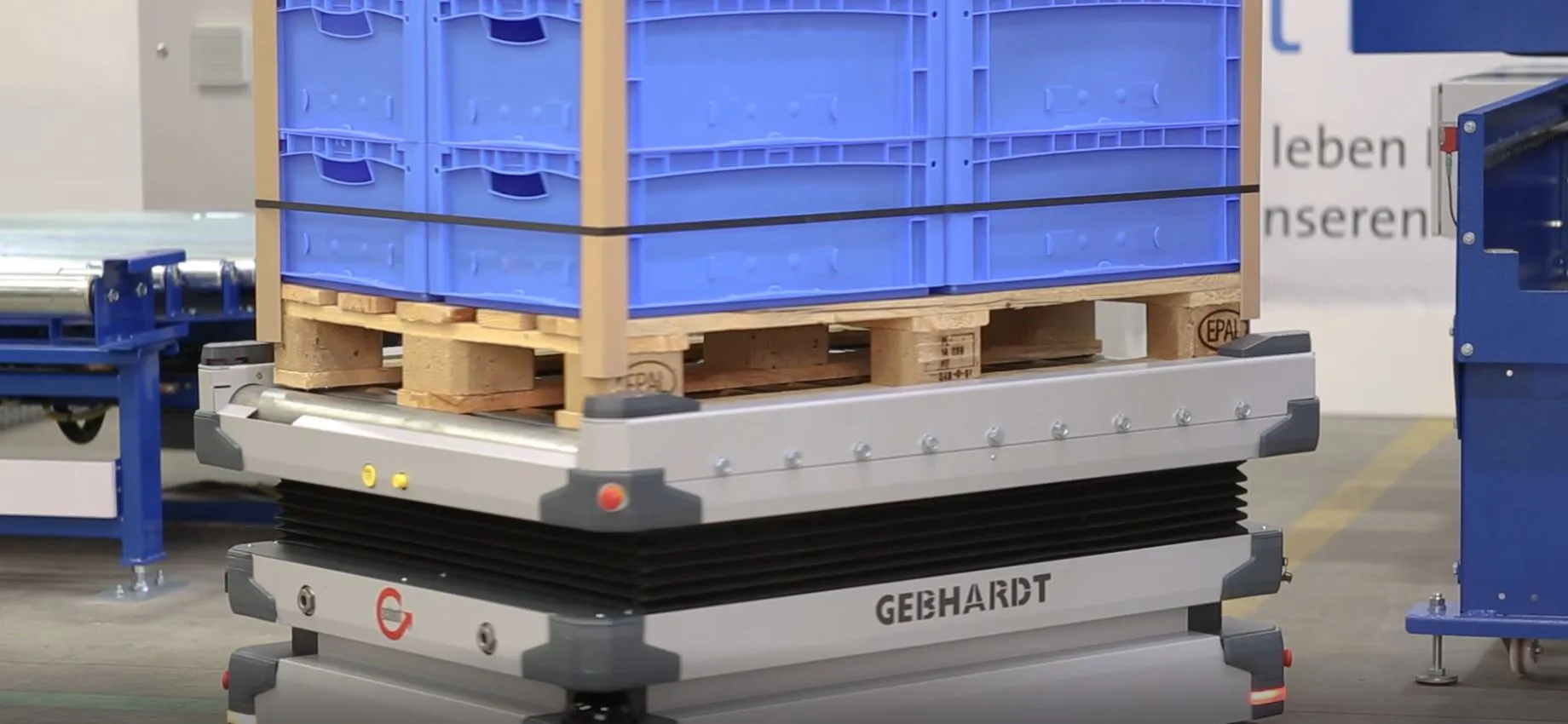

Finding the right system partner can be a challenge, but it doesn’t have to be. With over 40 years of experience, we have reliably optimized our entire line of strapping systems. We regularly partner with North American and global system suppliers to integrate a strapping capability into multi-function systems.

Working together with you, our team of expert engineers aims to provide the correct solution for your unique application. From simple “drop-in” strapping machines to a more complex customized solution that integrates into a more extensive system, we can provide a reliable, high-performing integrated solution.

At EAM-Mosca, we believe the strength of a system is about more than just the strapping machine. Our aftermarket services include technical support with highly trained technicians for on-site or remote troubleshooting and problem-solving, customer service for fast, easy strap and parts orders, and strapping materials designed to run smoothly and reliably with strong seals.

CONTACT US