Heavy Duty Side Sealer UHS-2-Sonixs Gets an Upgrade

As EAM-Mosca has moved aggressively into new markets with its Engineered Solutions division, side-seal strapping systems for securing shipping units have gained prominence in their sales program. The UHS-Sonixs was one of its initial entries in this market. Featuring the high performing Mosca Sonixs Unitizer strapping head and stretch resistant polyester strapping, this product quickly found its niche. However, early successes led EAM-Mosca design engineers to see even more potential with some modifications to the base machine design. The result is the aptly named UHS2-Sonixs.

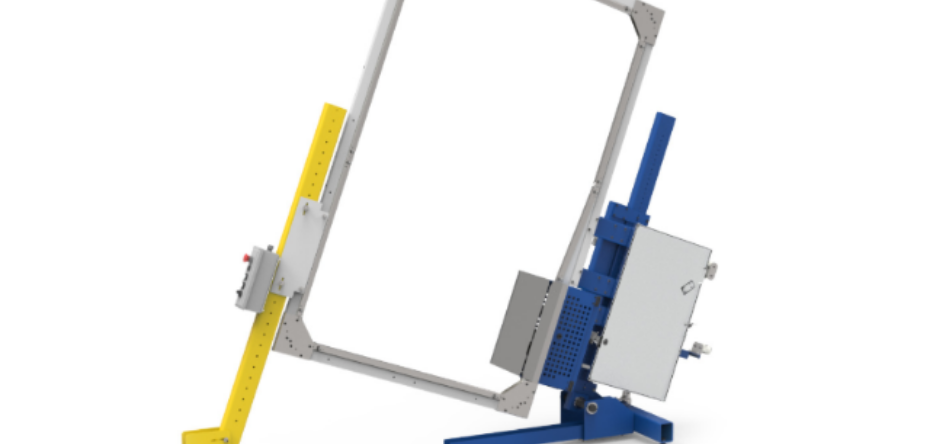

The UHS-2 structure is improved in several ways. Its floor space requirement from rear floor mount to sealer face has been reduced from about 60” to 28 ¾” while maintaining a low minimum conveyor height capability of 8.75”. The fixed position strapping head is now cantilevered over the floor structure allowing it to overhang conveyor by up to 14” depending on application requirements. Pool boxes, helpful for collecting pulled back strap on packages that are significantly smaller than the track opening, were standard on the original UHS. They are optional on UHS-2, saving space and expense in applications where package size is consistent and the pool boxes unnecessary. The electrical enclosure on UHS was located on the main machine structure. On UHS-2 the enclosure/operator control panel is freestanding and can be positioned in a location most convenient for specific applications and space availability. Finally, the portability feature of UHS was seen to be of little import, so it has been eliminated on UHS-2, whose fixed floor mount system allows its floor space requirement to be significantly reduced.

Adding operational flexibility, the minimum seal height above top of roller is reduced from about 14” to 6.2”. Building on experience in the window and door business, the machine is able to be tilted back up to 20 degrees to accommodate easel style assembly and packing lines.

Cycle reliability is a key performance feature of all process equipment, and strapping systems are no exception. UHS2 addresses this need with an improved track system. The spring gates on the UHS2 track feature a hemmed edge for smoother strap extraction and longer wear than the previous sheared edge components. In addition the track leg above the strapping head is angled away from the conveyor, promoting smooth strap escape from the track system on tall products that are positioned close to the face of the strapping head. UHS2 also offers an optional brush guidance system to assure accurate strap placement and reduce strap twist on packages that are significantly smaller than the track opening. Given the UHS2 max track opening possibility of 124” wide x 118” high, control of the strap during the pullback cycle is important, and each track design change contributes to improved strap management.

Beyond the noted changes, UHS2-Sonixs continues to use the versatile and very reliable Mosca Sonixs unitizer strapping head. It operates reliably with PP and PET strapping from 9mm to 12mm wide and up to 750 pounds breaking strength. The Sonixs sealing system has proven to be highly reliable, long lived and easy to maintain owing to its mechanical simplicity. It is smokeless, has no warmup time requirement, and has a self-monitoring capability to optimize seal strength on every strapping cycle.

The control system is built around a Siemens Series 7 processor. Operator controls include various cycle functions and automatic operation via signal exchange with an external controller.

While the original UHS-Sonixs has been a clear success in the marketplace, the increased versatility and reliability of the UHS2-Sonixs promises to expand its market applicability and the number of strapping users who appreciate its impressive capabilities.

EAM-Mosca Corporation provides high-performance strapping system solutions to a variety of industries, including food, graphic arts, mailing, fulfillment, logistics, corrugated, wood, and other industrial or consumer goods. We combine innovative equipment with strapping materials manufactured to maximize machine performance and customer support programs that help our customers meet their performance and productivity goals.

To learn more about any of EAM-Mosca’s other productivity enhancing strapping systems, please call us at 800-456-3420, or email us at info@www.eammosca.com. You can also connect with EAM-Mosca on YouTube (https://www.youtube.com/EAMMoscaCorp), Twitter (www.twitter.com/EAMMoscaCorp), and Facebook and LinkedIn via the links above.