Mosca Seals Leader Reputation with Sonixs

Hazle Township, PA – Most manufacturers give little thought to ‘end-of-line’ packaging like strapping. Belying that oversight is the fact that process problems at the end of the line can negatively impact throughput cost, delivery performance and perception of overall reliability as a supplier.

Mosca’s mission has always been to minimize strapping system faults by providing superior performance through technology leadership. It began with precision closed strap feed tracks, progressed to replacing mechanical drives with DC brushless motors, and currently features innovative ultra-sonic sealing to bind strap loops together in place of conventional heater blades and traditional mechanical friction weld technology.

Historically, the ultra-sonic sealing of plastics has been focused mainly on consumer packaging such as flexible packaging and clam shell packs. The challenge for Mosca was to create a space-constrained system that had the power to seal larger cross section strapping products with the flexibility to operate successfully in diverse manufacturing environments, often with more variability than continuous processes like the Form, Fill-Sealing of Flexible Packaging.

Enlisting a variety of university and industrial resources, the company introduced its Sonixs solution a few years ago and has been evolving it ever since. Today, Sonixs technology is used in equipment ranging from light duty bundling to demanding pallet unitizing applications, over a range of strap sizes and with both Polypropylene (PP) and Polyester (PET) straps. While Mosca still offers both heat blade and friction sealing options, Sonixs is fast becoming the sealing method of choice in most applications.

Sonixs advantages vs. heat blades are that it is smoke free, uses energy only during the seal cycle (less than 1/10th of a second per strap applied) and it eliminates all burn injury risk. Its seal strength is equal to or better than heat seals and sealing time is comparable. Because there is no residual resin retained on the sonotrode utilized in the Sonixs system our experience indicates that with equal levels of maintenance, Sonixs seal strength, compared to that of heat seal, remains more consistent over the machine life cycle. In certain applications, like pharmaceutical distribution, Sonixs’ distinctive imprint on the seal provides an enhanced level of security against tampering and theft.

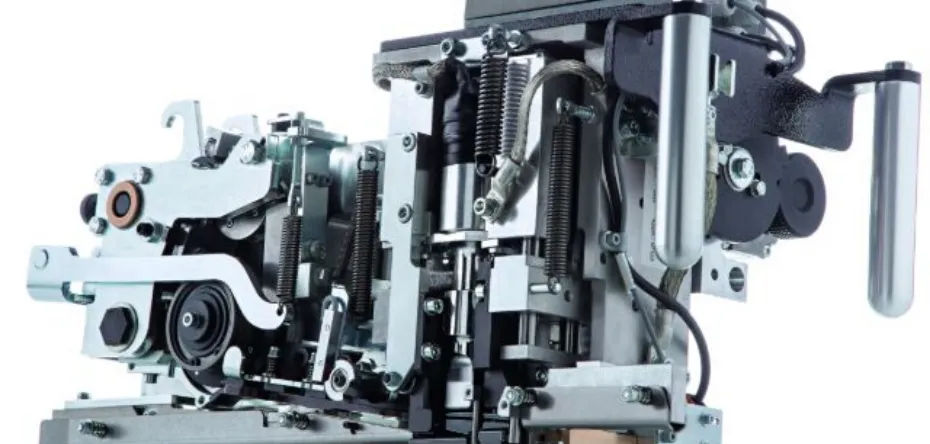

Compared to friction weld systems, Sonixs creates more consistent strap seals that are less affected by differences in strap surface characteristics and local operating conditions. More importantly, Sonixs is mechanically simpler, making only a short vertical move to transmit the sonic vibration, rather than a wear prone mechanism that fights the surface friction of the strap as it works to ultrasonically weld the interface to create the seal.

While the tendency of both users and strapping system manufacturers is to focus on creating inexpensive equipment, Mosca stands out as committed to utilizing technology to advance the performance of its strapping system solutions, in order to improve the productivity and lower the cost of our customers’ production processes, whatever they may be.

EAM-Mosca Corporation provides high-performance strapping system solutions to a variety of industries, including pharmaceutical, warehousing, corrugated, food, graphic arts, mailing, fulfillment, logistics, wood, and other industrial or consumer goods. The company combines innovative equipment with strapping materials manufactured to maximize machine performance, and customer support programs that help customers meet their performance and productivity goals. EAM-Mosca is headquartered in Hazle Township, Pennsylvania, USA, and was founded in 1982. Manufacturing facilities are located in Hazle Township and Ontario, Canada. Sales and service offices are located throughout North America, along with distributors and contract service providers in Central and South America, and sales/services offices in Monterrey, Mexico.

To learn more about any of EAM-Mosca’s other productivity enhancing strapping systems, please call us at 800-456-3420, or email us at info@eammosca.com. You can also connect with EAM-Mosca on YouTube, Facebook, Twitter and LinkedIn via links above.