Production Rate: Up to 40 bundles per minute

Track Size:

- Base: 500mm x 400mm, 600mm x 600mm, 800mm x 600mm

- Pro: 500mm x 600mm, 600mm x 600mm, 800mm x 600mm, 800mm x 800mm, 1000mm x 1000mm

Electrical: 100-600V, 50/60hz, 1 Ph 0.25 KVA

Controls:

- Base: Push button panel operator interface (upgrade to Pro controls available)

- Pro: B&R PLC/HMI with advanced controls

Air Requirements: Pneumatic press option: 3 CFM @87 psi

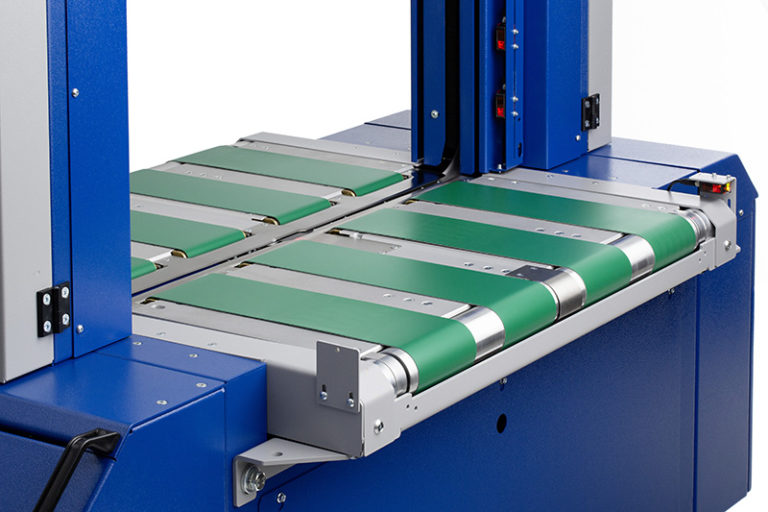

Table:

- Standard: Belt conveyor 3” between center belts

- Optional: Roller conveyor

Table Height:

- Standard: 27.6” (700mm) – 34.3” (870mm)

- With Risers: 34.3”(870mm) – 40.9” (1040mm)

Strapping: SoniXs® sealer runs PP strap and select PET strap 5mm, 6mm, 8mm, 9mm, 12mm

Strap Tension: Infinitely adjustable up to 60 lbs.

Strap Seal: SoniXs® Ultrasonic seal with DC brushless direct drive motor

Seal Location: Base & Pro: All sizes availaible in Center seal or Offset

Machine Shipping Weight: Approx. 900 Lbs.

Casters: Four swivel-lock casters.Two stabilizing feet