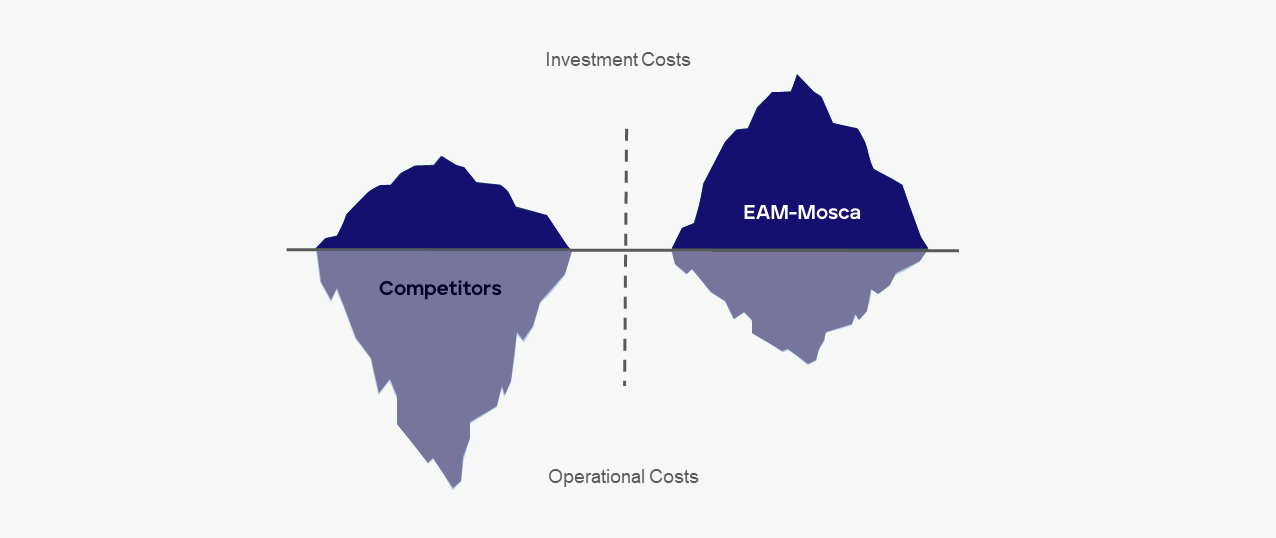

Top 5 Ways To Calculate TCO

01. Initial investment

It’s important to define system requirements accurately so that suppliers quote appropriate solutions. In addition to the equipment purchase price, consider space requirements, installation, and training requirements.

At EAM-Mosca, we perform an in-depth analysis of your particular application to assess what solution is required. Our engineers often customize a system to ensure the best solution rather than an inefficient one-size-fits-all approach. Up and downstream material handling equipment integrations with the strapping system also minimize production disruptions lowering costs after the initial purchase.

Learn More About Customized Solutions

02. Operating Costs

Elements of operating cost include utility costs, system speed vs. production requirements, and the cost of strapping.

System speed should match production processes with some allowance for peak requirements. Some redundancy may best serve critical processes in the system to assure the ability to meet the highest production demands.

Strapping cost is another critical variable. Unlike some strapping system suppliers, EAM-Mosca ensures the strap used is the lightest needed to secure the package without losing reliability or performance, increasing cost savings while reducing waste material.